Services

Engineering, Procurement & Construction (EPC)

Turnkey project delivery across power generation and distribution.

Plant Rehabilitation

Equipment modernization to improve reliability and extend plant life.

Supply & Testing

Procurement, factory acceptance and site testing by certified teams.

Battery Banks & Rentals

Temporary and long-term backup power solutions with on-site testing.

Investment & Feasibility

Financial studies and feasibility assessments for energy projects.

Projects

Supply, Installation, Testing and Commissioning of Hybrid Solar

Upgrade and Replacement of Solar Inverter

Total Upgrade of Data Center Uninterruptible Power Supply

Supply Installation and Testing of 125 VDC Battery Banks

34.5 KV CT AND PT Replacement

Construction of Automatic Voltage Regulator

Supply and Installation of SF6 145 KV

Supply Service Agreement of Various Wires and Cables

Supply and Delivery of CT, VT and CVT

Supply, Delivery and Testing of Fuji Electric Transformer

Procurement of 5KV SF6 Switchgear

Supply and Installation of Engineered Ship Fenders

Rehabilitation of Dosing System

Procurement and Construction of Fire Engine

Delivery of Various Valves, Fittings, Pipes and Flanges for Geothermal Steam Product

Supply and Installation of Cooling Tower Gearbox

Supply and Delivery of Drill Bit

Supply and Delivery of Filter Leaves

Instrumentation System Rehabilitation (Upgrade and Reliability)

Supply, Installation, Testing and Commissioning of Hybrid Solar

Location: Mindanao, Philippines

This project involved the deployment of a hybrid solar power system designed to enhance operational energy efficiency through renewable generation. The team handled the full cycle from supply to commissioning, ensuring safe and reliable integration into existing electrical infrastructure.

Scope of Work

- Supply of hybrid solar equipment and balance-of-system components

- Installation of solar modules, supports, electrical wiring, and protections

- Integration with existing facility electrical systems

- Testing, calibration, and final commissioning

Key Highlights

- Improved energy resilience using renewable generation

- Delivered full compliance with NGCP safety requirements

- Validated system performance during commissioning

Outcome

The hybrid solar system was successfully energized and turned over to the client, delivering improved system efficiency and long-term operational sustainability.

Upgrade and Replacement of Solar Inverter

Location: Burgos, Ilocos Norte

This project involved the upgrade and full replacement of existing inverter units to enhance solar array efficiency and system stability. The work included detailed assessments, installation of high-performance inverter models, and performance validation under operational conditions.

Scope of Work

- Assessment of the existing inverter configuration

- Supply and installation of upgraded inverter equipment

- Electrical integration, wiring optimization and protection updates

- Performance testing, tuning and commissioning

Key Highlights

- Improved solar energy conversion efficiency

- Reduced maintenance-related downtime

- Delivered complete test, tuning and compliance documentation

Outcome

The upgraded inverter system was commissioned successfully, resulting in greater operational reliability, improved energy yield and increased long-term system performance.

Total Upgrade of Data Center Uninterruptible Power Supply

Location: Quezon City, Metro Manila

This project delivered a full modernization of the facility’s UPS infrastructure to enhance power stability, equipment protection and overall data center reliability. The work included structured replacement of legacy components, upgrading critical power paths and validating performance under operational load conditions.

Scope of Work

- Assessment of existing UPS equipment and system architecture

- Supply and installation of upgraded UPS modules and components

- Integration with facility critical loads and switching systems

- Load testing, performance tuning and commissioning

Key Highlights

- Improved power continuity for mission-critical operations

- Optimized system efficiency and reduced thermal load

- Enhanced redundancy and protection settings

Outcome

The upgraded UPS system achieved full operational acceptance, providing NGCP with strengthened backup capacity, improved resilience, and stable power protection for data center operations.

Supply Installation and Testing of 125 VDC Battery Banks

Location: Nationwide (40 sites)

This project involved the complete deployment of a 125 VDC battery bank system designed to support substation operations, protection equipment, and emergency backup requirements. The installation ensured stable and dependable DC power for mission-critical utility processes.

Scope of Work

- Supply of battery banks, racks, terminal hardware, and safety components

- Assembly and installation of battery modules with proper ventilation layout

- Cabling, termination, labeling, and integration with the existing DC system

- Conducting voltage checks, functional tests, and full commissioning

Key Highlights

- Improved reliability for protection relays and control circuits

- Extended runtime capability during power interruptions

- Compliant with NGCP battery handling and electrical safety standards

Outcome

The 125 VDC battery bank system was successfully commissioned, providing continuous and dependable DC supply essential for the client’s operational safety and reliability.

34.5 KV CT AND PT Replacement

Location: Manolo Fortich, Bukidnon

The project involved the replacement of existing 34.5 kV current transformers (CT) and potential transformers (PT) to improve system reliability, measurement accuracy, and protection performance. The work ensured proper alignment with updated safety, metering, and protection standards.

Scope of Work

- Removal and safe isolation of existing CT and PT assemblies

- Installation of new 34.5 kV CT and PT units with correct mounting and alignment

- Connection, wiring verification, insulation testing, and polarity checks

- Integration with metering, SCADA, and protection systems

- Final testing and commissioning prior to energization

Key Highlights

- Upgraded transformer accuracy for improved system monitoring

- Reduced outage risks through modernized protection components

- Compliance with First Gen and industry electrical safety standards

Outcome

The new CT and PT units were successfully commissioned, resulting in improved reliability, enhanced measurement accuracy, and strengthened protection performance across the facility’s electrical network.

Construction of Automatic Voltage Regulator

Location: San Pedro, Laguna

This project delivered a fully engineered Automatic Voltage Regulator (AVR) designed to stabilize and regulate electrical voltage for critical operations. The AVR system was constructed to improve equipment protection, operational safety, and overall power quality across the facility.

Scope of Work

- Design and fabrication of the AVR enclosure and control assembly

- Integration of voltage regulation modules, sensors, and safety relays

- Cabling, termination, protection device setup, and system wiring layout

- Testing, fine-tuning, and commissioning before deployment

Key Highlights

- Enhanced voltage stability for sensitive equipment

- Reduced risk of equipment damage due to voltage fluctuations

- Fully compliant with industrial electrical safety and design standards

Outcome

The constructed AVR system was successfully commissioned and delivered, providing consistent and reliable voltage regulation that supports the client’s operational requirements and electrical safety.

Supply and Installation of SF6 145 KV

Location: NPC Mingen

This project provided a complete supply and installation of a 145 kV SF6-insulated apparatus, supporting high-voltage switching and protection applications. The work ensured safe integration into the client's existing substation environment while meeting strict operational and safety requirements.

Scope of Work

- Delivery of SF6-insulated 145 kV switchgear and accessories

- Assembly, installation, and structural alignment of equipment

- Gas handling, filling, leak testing, and safety validation

- Electrical integration, functional checks, and commissioning

Key Highlights

- High-voltage equipment installed according to OEM and industry standards

- Improved switching reliability and insulation performance

- Compliance with NPC safety, environmental, and operational guidelines

Outcome

The 145 kV SF6 system was fully commissioned, improving switching reliability and strengthening the facility’s high-voltage operational capability for long-term service.

Supply Service Agreement of Various Wires and Cables

Location: Nationwide (40 sites)

This agreement covered the supply and delivery of various wires, cables, and related fittings essential for grid maintenance, reliability upgrades, and system reinforcement activities within NGCP facilities nationwide.

Scope of Work

- Procurement of power cables, control cables, and specialty wiring

- Quality inspection, material certification, and compliance verification

- Packaging, logistics, and transport coordination for site deliveries

- Support for NGCP technical teams during material acceptance

Key Highlights

- Materials sourced from accredited and industry-compliant suppliers

- Ensured timely deliveries aligned with NGCP maintenance schedules

- All materials passed inspection and conformance requirements

Outcome

The project facilitated uninterrupted supply of essential cabling materials, supporting NGCP’s operational continuity and ongoing grid reinforcement programs.

Supply and Delivery of CT, VT and CVT

Location: NGCP (40 sites)

This project involved the supply and delivery of Current Transformers (CT), Voltage Transformers (VT), and Capacitive Voltage Transformers (CVT) used for measurement, protection, and supervisory functions across high-voltage substation facilities.

Scope of Work

- Procurement of CTs, VTs, and CVTs based on NGCP-approved specifications

- Inspection and certification according to electrical industry standards

- Secure packaging and logistics arrangement for delivery

- Coordination with NGCP teams during receiving and acceptance

Key Highlights

- Materials sourced from reputable, NGCP-accredited manufacturers

- Equipment designed for accuracy, reliability, and long-term operation

- Delivered complete documentation for testing and compliance

Outcome

The transformers were delivered on schedule and fully accepted by NGCP, supporting ongoing substation performance improvements and system protection requirements.

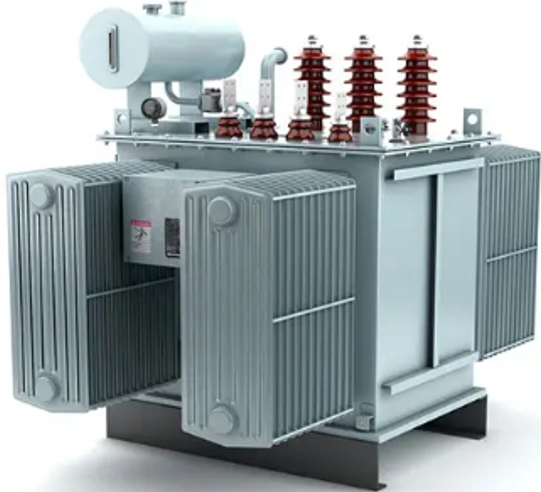

Supply, Delivery and Testing of Fuji Electric Transformer

Location: Kalayaan, Laguna

This project covered the supply, delivery, and performance testing of a Fuji Electric power transformer designed to support high-reliability operations. The unit was prepared, inspected, and validated to ensure conformance with the client’s operational and protection requirements.

Scope of Work

- Supply of Fuji Electric transformer and required accessories

- Transportation, handling, and secured delivery to site

- Inspection and verification of nameplate and technical parameters

- Conducting electrical testing, insulation checks, and performance validation

Key Highlights

- Transformer sourced directly from a certified and reputable manufacturer

- Testing procedures aligned with industry and OEM standards

- Delivered complete documentation including test reports and certifications

Outcome

The Fuji Electric transformer passed all required acceptance tests and was formally turned over, providing the client a dependable and efficient power distribution asset.

Procurement of 5KV SF6 Switchgear

Location: Bacman, Sorsogon

This project involved the procurement of 5kV SF6-insulated switchgear units designed for medium-voltage protection, switching, and operational reliability. The equipment supports critical functions within the client’s power generation and distribution systems.

Scope of Work

- Supply of 5kV SF6-insulated switchgear assemblies

- Verification of technical specifications and OEM documentation

- Inspection, quality validation, and shipment preparation

- Coordination for safe and secure delivery to the client’s facility

Key Highlights

- Equipment sourced from certified and industry-compliant manufacturers

- Enhanced protection performance through SF6-insulated switching technology

- Delivered complete technical, safety, and compliance documents

Outcome

The switchgear was delivered in full compliance with project specifications, contributing to improved operational safety and medium-voltage system reliability for the client’s facility.

Supply and Installation of Engineered Ship Fenders

Location: Bawing, General Santos

This project supplied and installed engineered ship fenders designed to protect docking structures and ensure safe berthing operations. The work involved custom-fabricated components suited for marine loading facilities and high-impact operational environments.

Scope of Work

- Procurement of engineered marine fender units and mounting assemblies

- Fabrication and preparation of brackets, plates, and support hardware

- Installation on existing berthing structures with proper alignment

- Inspection, impact testing, and final onsite validation

Key Highlights

- High-durability fender materials designed for industrial marine operations

- Enhanced protection for ships and structures during berthing

- Completed installation in compliance with safety and marine standards

Outcome

The engineered ship fenders were successfully installed and certified, improving safety and operational performance at the client’s loading facility.

Rehabilitation of Dosing System

Location: Masinloc, Zambales

This project focused on restoring and upgrading the plant dosing system to ensure accurate, efficient, and safe chemical handling. The rehabilitation addressed worn components, calibration issues, and system performance gaps affecting operational reliability.

Scope of Work

- Assessment of the existing dosing equipment and pipelines

- Replacement of damaged mechanical components and fittings

- Reconditioning of pumps, valves, and control accessories

- Calibration, leak testing, and operational verification

Key Highlights

- Improved dosing accuracy and reduced chemical wastage

- Restored mechanical integrity for safer plant operations

- Completed system validation under operating conditions

Outcome

The rehabilitated dosing system significantly enhanced performance, improving operational safety and enabling stable, consistent chemical processing for the facility.

Procurement and Construction of Fire Engine

Location: Iligan City, Lanao Del Norte

This project covered the full procurement and construction of a specialized fire engine designed to meet industrial emergency response requirements. The unit was engineered with durable components, safety features, and performance systems suitable for plant operations.

Scope of Work

- Procurement of chassis, pump systems, storage assemblies, and firefighting components

- Fabrication and construction of the fire engine body and structural frame

- Installation of pumps, valves, controls, nozzles, and emergency equipment

- Full system testing, certification, and delivery to the client

Key Highlights

- High-reliability pump and suppression equipment installed

- Engineered for industrial-grade emergency readiness

- Delivered with complete operational testing and documentation

Outcome

The constructed fire engine met all functional and safety specifications, strengthening the client’s emergency response capacity and operational safety protocols.

Delivery of Various Valves, Fittings, Pipes and Flanges for Geothermal Steam Product

Location: Ormoc, Leyte

This project ensured the procurement and timely delivery of high-grade valves, fittings, pipes, and flanges intended for geothermal steam operations. All supplied components were sourced according to the client’s specifications and matched for high-temperature, high-pressure service conditions.

Scope of Work

- Procurement of valves, fittings, pipes, flanges, and related hardware

- Inspection for quality, certification, and material compliance

- Proper packaging and logistics planning for site delivery

- Coordination with EDC personnel during receipt and verification

Key Highlights

- All components sourced from approved and certified suppliers

- Materials selected for geothermal steam durability and operational safety

- Delivered complete documentation including test certificates and specifications

Outcome

The delivered materials passed acceptance checks and supported EDC’s geothermal maintenance and system enhancement activities, ensuring continuous plant reliability.

Supply and Installation of Cooling Tower Gearbox

Location: Makban, Laguna

This project involved the complete supply and installation of a cooling tower gearbox designed to enhance mechanical reliability, improve torque transfer, and support stable cooling tower operations. The installation was performed in accordance with OEM specifications and plant safety standards.

Scope of Work

- Supply of cooling tower gearbox and required mounting hardware

- Alignment, leveling, and preparation of the mechanical support assembly

- Installation of gearbox, coupling components, and lubrication system

- Operational testing, adjustment, and final commissioning

Key Highlights

- Improved mechanical performance and reduced vibration levels

- Gearbox sourced from accredited and compliant manufacturers

- Work executed under strict mechanical and safety standards

Outcome

The newly installed gearbox significantly improved cooling tower efficiency and mechanical reliability, reducing downtime and enhancing long-term operational performance for the client.

Supply and Delivery of Drill Bit

Location: Santiago, Isabela

This project covered the procurement and supply of industry-grade drill bits used for geothermal, industrial, and maintenance operations. All units supplied underwent quality verification to ensure proper material strength, durability, and performance under high-demand conditions.

Scope of Work

- Supply of precision-engineered drill bits based on required specifications

- Inspection and verification of material integrity and dimensional accuracy

- Packaging, logistics handling, and secure delivery to client site

- Provision of manufacturer certifications and compliance documents

Key Highlights

- Delivered drill bits with high wear resistance and long service life

- Compliance with industry safety and performance standards

- Assured compatibility with existing drilling systems and tools

Outcome

The supplied drill bits met all required specifications and were accepted for operational use, supporting the client's drilling and maintenance activities with reliable performance.

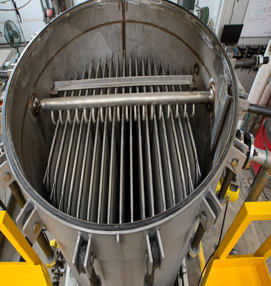

Supply and Delivery of Filter Leaves

Location: Batangas City

This project involved the supply of high-performance filter leaves used in industrial filtration systems. These components are essential in refining processes, ensuring efficient separation, long service life, and stable plant operations.

Scope of Work

- Procurement of filter leaves based on client specifications

- Quality inspection and verification of material compatibility

- Packaging and safe transport to prevent deformation or contamination

- Delivery scheduling coordinated with plant operations

Key Highlights

- Ensured product quality aligned with filtration performance standards

- Delivered components suitable for high-temperature and continuous-process applications

- Provided manufacturer certifications and technical documentation

Outcome

All filter leaves were successfully delivered, verified, and accepted by the client, enabling continuous and efficient operation of the facility’s filtration systems.

Instrumentation System Rehabilitation (Upgrade and Reliability)

Location: Ormoc, Leyte

This rehabilitation project focused on upgrading critical instrumentation systems to enhance plant reliability, monitoring accuracy, and operational safety. The work involved replacing aging components, improving signal integrity, and modernizing control interfaces aligned with current industry standards.

Scope of Work

- Assessment and mapping of existing instrumentation loops and control elements

- Replacement of obsolete field instruments, transmitters, sensors, and cabling

- Integration with updated SCADA / DCS systems and improved signal routing

- Calibration, loop testing, and commissioning of upgraded instrumentation

Key Highlights

- Improved measurement accuracy and reduced error margins

- Enhanced reliability through updated instrumentation technology

- Better control responsiveness and safer plant operation

Outcome

The upgraded instrumentation system now provides higher operational reliability and improved monitoring accuracy, supporting more efficient and safer plant processes for the client.

Our Clients

Technical Partners & Manufacturers

About Us

Technozone Corporation is a Philippine-based Engineering, Procurement and Construction (EPC) company specializing in energy and power system solutions. Established in 2003, the company has built a strong reputation in delivering high-quality electrical, mechanical and instrumentation works for major utilities, industrial facilities and power generation companies across the country.

Mission

To acknowledge our responsibilities as industrialists and to dedicate ourselves to the progress and development of the industry as well as the well being of people through our business.

Vision

To deliver excellent performance beyond comparison to our clients.

Our Core Values

Excellence

We strive to deliver the very best in all areas of work.

Integrity

We value honesty, transparency, and fairness.

Innovation

We embrace new methods that deliver better results.

Teamwork

We work together towards a common goal.

Our Story

Founded in 2003, we began as a small team with big dreams to transform the engineering landscape in the Philippines. Through dedication and innovation, we've grown into a nationally recognized leader in technical solutions.

Our early years were marked by groundbreaking government projects that established our reputation for excellence. We expanded nationwide, bringing our expertise to diverse industries and communities.

Today, with ISO 9001:2015 certification and numerous industry recognitions, we continue to push boundaries while staying true to our founding values.

Our Management Team

Reynante C. Manio

Founder & President

Leads the company’s overall direction and growth, ensuring strategic alignment and operational excellence.

Mahlet T. Manio

Vice President

Oversees Finance and Administrative operations.

Sharmaine M. Manio

General Manager

Oversees engineering and industrial sales operations.

Marby Mei T. Tayo

Finance & Admin Assistant Manager

Handles Finance, Admin, Logistics & ISO Facilitation.

Daichi Z. Matsuzawa

Sales Assistant Manager

Manages Sales & Marketing operations.

Ann Cheslyn D. Canonigo

Finance & Admin Supervisor

Oversees Finance, Accounting & ISO Lead Auditor.

Mia L. Lusuegro

Quality Control Supervisor

Oversees Quality Control & ISO compliance activities.

Our Products

Instrumentation & Control Products

Mechanical Products

Electrical Products

Renewable Power Plant Products

Drilling Products

Contact Us

sales@technozone.com.ph

(049) 513-5425

RCM Building, B4A L20, One Asia Business Center,

Jubilation Road, Biñan, 4024 Laguna

Procurement and Construction

Client: Petron Corporation

Design, Procurement and Construction

Client: AES Masinloc

Upgrade of dosing system and related works.

Procurement and Construction

Client: Firstgen Hydro Power Corporation

CT and PT Replacement — Manolo Fortich, Bukidnon.

Our Humble Beginnings

Technozone Corporation was established in 2003 by Mr. Reynante C. Manio.

South Lake Heavy Industries

Fabrication and erection of large and heavy equipment. Project management and technical teams available.